High Power, High Reliability, High Performance

Clean, efficient energy in industry, transportation and communications

The world outside your home is a complex network of energy, data and material movements. From creating electrical energy via renewable sources, to factory robotics and automation, elevators and escalators, autonomous EV deliveries, and fast, effective mass-transit, next-generation GaN and SiC power semiconductors deliver efficient, clean, and powerful solutions.

Renewable Energy

Solar energy is the great success of the renewable revolution, with cell efficacy doubling since 1990, now reaching almost 30% in mass production and up to 40% in academia. Installed solar power capacity is expected to exceed that of natural gas in 2026, and of coal by 2027, becoming the largest in the world, a 3x increase in installed capacity from 2022-2027. The global levelized cost of electricity from solar is now around 40% lower than coal and natural gas.

String Inverters

In typical large-scale commercial / industrial solar installations, individual panels are ‘strung’ together which creates 10’s kW of DC power at high voltages, usually over 1,000 V. A ‘string inverter’, converts the high-voltage DC to an AC voltage, typically 110 or 240 V which is fed into the main distribution grid, or converted back to a low voltage (48 V) DC for on-site battery storage.

GeneSiC silicon carbide (SiC) power MOSFETs, from 1,200 V to 6,500 V are ideal, fast-switching power components that enable high-efficiency, small size, and lower system cost string inverters.

Generators

In wind (and wave) energy applications, a rotating mechanical motion is converted to electrical power using a generator (or dynamo). High-power turbines require high-current, high-voltage devices, such as GeneSiC 3,300 V or 6,500 V silicon carbide (SiC) power MOSFETs and diodes, available in a broad range of RDS(ON) values and packages.

Mass-transit

Today’s efficient, clean and fast mass-transit is a network of buses, trams and passenger railways.

Rail

Pure-electric trains enable a faster (top speed and acceleration), more efficient, and quieter travel experience than diesel, with zero CO2 at point-of-use.

Modern electrified rail lines use high-voltage overhead catenary to carry 25,000 V which is collected via pantograph and then stepped-down to drive high-speed, high-power wheel-mounted motors.

Voltage regulators and traction inverters require GeneSiC 3,300 V or 6,500 V silicon carbide (SiC) power MOSFETs and diodes, available in a broad range of RDS(ON) values and packages, and also in bare-die (unpackaged) formats for rugged, high-power, high-voltage modules.

Within passenger trains (and buses), a vast array of applications require reliable power, from lighting and WiFi, to location tracking / announcements, advertising displays, AC power for passenger laptop and phone chargers, etc. Application power can range from 10s to 100s W, and GaNFast gallium nitride (GaN) power ICs offer efficient, small, low system-cost power conversion solutions.

Buses

As with EV passenger cars, electrification of mass transit with next-gen gallium nitride (GaN) and silicon carbide (SiC) enables:

- Up to 3x faster charging

- Up to 70% energy savings

- Longer range

- Lighter weight

- Faster acceleration

- Lower cost

- Safer operation than legacy silicon chips.

Buses (and trucks) can also act as supplementary energy back-up for clinics, schools, emergency services, etc., and be a critical part of an energy-independent micro-grid in the event of a mains AC failure. This is known as “V2x” (vehicle to anything) charging, and can be:

- V2V – one VE charges another

- V2G – power returns to the AC grid, and

- V2H – your EV powers your home

On-Board Charger (OBC)

The OBC takes in AC power and converts to a high-voltage (800 V) DC power for the EV’s on-board battery. With superior high-voltage capability, 1,200 V and 1,700 V GeneSiC MOSFETs and diodes connect efficiently and reliably to 800 V battery systems.

OBCs for buses and trucks range from 50 kW to 600 kW, and due to higher switching speeds, and higher efficiency, SiC OBCs can be up to 3x smaller – or provide 3x more power for 3x faster charging – than legacy silicon systems.

A key development in EV OBCs is ‘bi-directionality’ – which means that the car is no longer simply an energy use, or load, but can be an energy source as in “V2x” mentioned earlier.

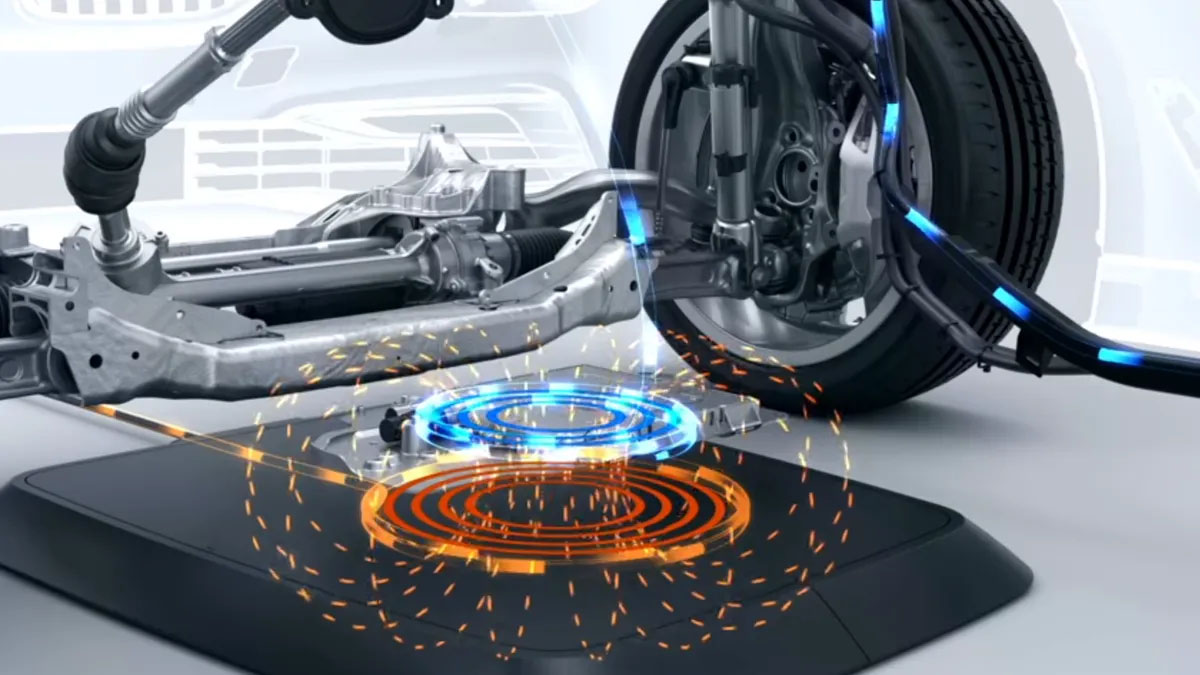

Wireless Charger

Source: BMW

As with 4-passenger EVs, buses and trucks may benefit from optimized ‘contact-less’ power. For example, in commuter routes where a bus can be charged from beneath in the dwell time at a bus stop, while passengers enter and exit, when taxi drivers are waiting for a fare, or where AI warehouse robots can be charged at a remote location without a human to connect and disconnect charging cables. A pilot bus scheme began back in 2014, in Milton Keynes, UK, and proved efficient and reliable.

In the ‘light duty’ EV market, an industry standard – SAE J2954 was ratified in 2018, and updated recently in October 2022 to define power ranges (3.3 – 11 kW) and frequency (81.39 – 90 kHz) to allow interoperability.

Silicon carbide (SiC) has higher-speed performance (lower capacitance) than legacy silicon chips, so operates more efficiently with cooler, longer-lifetime operation.

Traction Inverter (Motor Drive)

The traction inverter takes power from the battery and uses it to turn the main motor(s) in the EV, usually in a 3-phase bridge architecture. High-efficiency, high-speed, high-reliability GeneSiC silicon carbide (SiC) MOSFETs are optimized for these high-voltage, high-current conditions, and range from 650 to 6,500 V.

Running at high frequency shrinks the drive stage by 3x, with lower weight and system cost, with estimated performance of over 99% peak efficiency, and up to 10% longer range.

DC-DC Converter

While high-power functions – like the main traction drive – are connected directly to the high-voltage (800 V) battery stack, many applications like navigation systems, ‘kneeling’ suspension, seat motors, windshield wipers, etc. are low voltage, usually 24 V.

DC-DC converters step down the voltage and provide safety isolation, using 1,200 V GeneSiC devices at high speed with up to 20% energy savings, up to 3x smaller, up to 20% lighter, plus the reduced cost of passive components.

Air-Conditioner (AC) Compressor

Air-conditioners cool the passenger compartment using the classic refrigeration technique of increasing the pressure of a liquid, which then cools as it expands. In an EV, the compressor is typically a 3-phase motor drive, with SiC MOSFETs chosen per the battery voltage.

Compared to legacy silicon IGBTs, SiC compressor drive stages can be up to 3x smaller, with over 98% efficiency.

For 800 V systems, learn more about 1,200 V and 1,700 V GeneSiC MOSFETs and diodes.

Cabin Heater (PTC)

GeneSiC SiC MOSFETs have the industry’s smallest increase in resistance over temperature – which in the vast majority of applications is a critical advantage in efficiency and reliability. In a cabin heater, this small increase in resistance is used in a self-regulating, safe, efficient way to provide heat to the EV’s passenger compartment.

‘PTC’ stands for ‘positive temperature coefficient’ and as the temperature increases, the resistance of the SiC MOSFET increases, and current is reduced or stopped automatically.

Compared to silicon IGBTs, SiC systems have higher efficiency (>95%), are smaller and lighter.

Elevators and Escalators

In so many apartment blocks, offices, shopping malls, sports stadia, and airports, we rely on safe, efficient, quiet elevators and escalators to move us around.

High-power (15-75 hp / ~10-50 kW) traction motors use silicon carbide MOSFETs and diodes to efficiently power three-phase synchronous drive motors. Based on the power, a range of GeneSiC devices from 1,700 V to 6,500 V are selected.

Lower-power converters are also required to drive information / advertising screens, LED lighting, floor control schemes, and for which GaNFast power ICs are ideal.

Data Centers & Communications

![datacenters[1]](https://navitassemi.com/wp-content/uploads/2021/08/datacenters1.jpg)

Our modern world relies critically on constant communication and data processing, from in-car navigation and package delivery tracking, to streaming TV and workplace video communications, like Zoom.

The ‘silicon chip’ has been the backbone – indeed the enabler – of the data revolution, both in terms of data processing in CPUs, GPUs, memory, networking, etc. and in terms of power conversion from high-voltage AC all the way down to the 1V needed by the microprocessor. The problem is that silicon as a power conversion platform has hit its physical limits and it’s time for a new semiconductor – gallium nitride (GaN) – to take its place. A worldwide Si-to-GaN data center upgrade would reduce energy loss by 30-40%, which would translate as saving over 100 TWh and 125 Mtons of CO2 emissions by 2030.

As high-voltage, 3-phase AC power enters the data center, silicon carbide MOSFETs and diodes are replacing silicon IGBTs in two functions; to step-down and isolate to 220 V AC to feed each server rack, and to provide fault-protection in UPS systems.

From 220 V AC, GaN power ICs are replacing silicon MOSFETs in power-factor correction (PFC) and DC-DC stages in ‘silver box’ power supplies, delivering 12 V or 48 V of DC power to server blades. Navitas’ dedicated data center system design develops complete platform designs, such as 2,700 W AC-12V, to show customers how high-speed, high-efficiency GaN power ICs shrink the amount of rack space required for power, and so increase the space available for data processing and communications.

Factory Automation

Modern factories and distribution warehouses rely on a finely-integrated network of automated and autonomous robots, conveyors, drones and more. Modular functions enable more efficient operation, for example conveyors need only operate small sections of belt (or wheels) when a package is present, or if there is a breakdown, only a small part of the factory is affected while maintenance occurs.

Depending on size and weight-carrying capability, robots operate using voltages from 12 V to 400 V DC, allowing the use of GaN power ICs for power conversion and inverter drives. SiC MOSFETs and diodes may also be used in very high-power robots in cases like automotive manufacturing. Both GaN and SiC operate faster, cooler and more efficiently than legacy silicon MOSFETs, shrinking the size, weight and cost of converters in inverters, plus extending life-time reliability.

In 400 V DC bus systems, with DC-DC ‘brick’ converters, GaNFast power ICs operate 4x faster than silicon, delivering 80% energy savings and 4x smaller size.

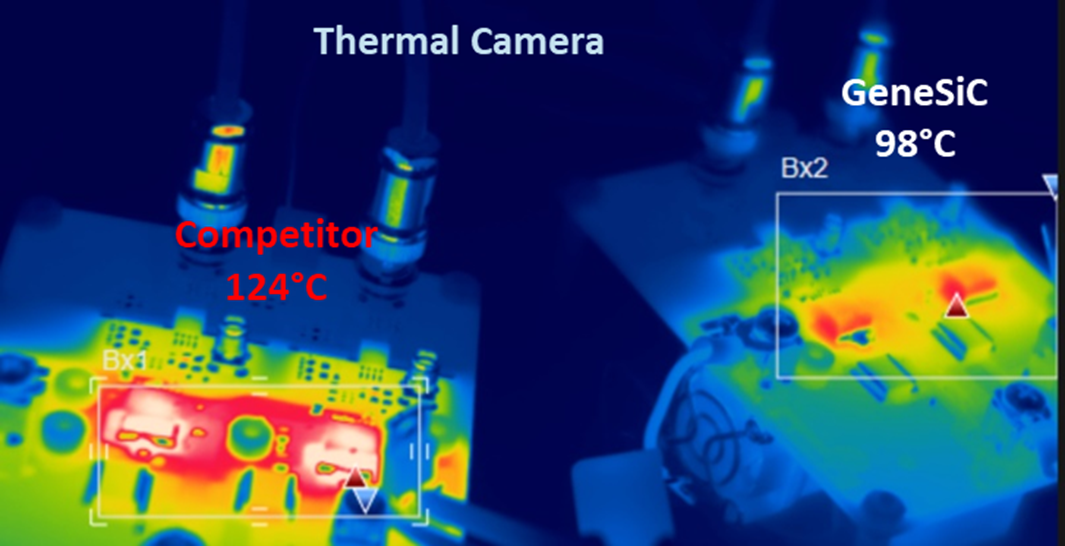

GeneSiC MOSFETs use optimized trench-assisted planar gate technology to reduce losses at high temperatures and high speeds compared to competitors.

For more detail on GeneSiC silicon carbide power MOSFETs and didoes, click here.

Pallet-trucks, forklifts and autonomous material-handling robots benefit from the same GaN/SiC advantages as passenger EVs and mass transit. In each case delivering energy savings, cool operation and smaller size vs legacy silicon chips.