Autonomous GaN Power ICs Deliver HighPerformance, Reliable Motor Drives

![27_Pdf_File_Type_Adobe_logo_logos-512[1]](https://navitassemi.com/wp-content/uploads/2020/12/27_Pdf_File_Type_Adobe_logo_logos-5121.png)

Autonomous GaN Power ICs Deliver HighPerformance, Reliable Motor Drives

By Alfred Hesener, Senior Director Industrial and Consumer

Navitas’ GaNFast™ power ICs with GaNSense™ technology enable ‘detect and protect’ in 30 ns

Motor Drives: Enabling Technology to “Electrify Our World™”

There are about 8 billion electric motors in use in the EU, consuming nearly 50% of the electricity the EU produces [1]. As improving efficiency and reducing carbon footprint are key goals for governments and industry, multiple initiatives exist to make these motors less power hungry. For example, the many worldwide standards for energy labeling of household appliances impact the design of appliances by targeting lower energy consumption, audible and electrical noise, among others [2]. Another example is the introduction of efficiency classes for industrial motors in Europe, effectively cutting off lower efficiency motors from the market [3,4]. As a result, we have seen the rise of induction motors, such as brushless DC (BLDC), which are smaller and more efficient for the same mechanical power [5,6].

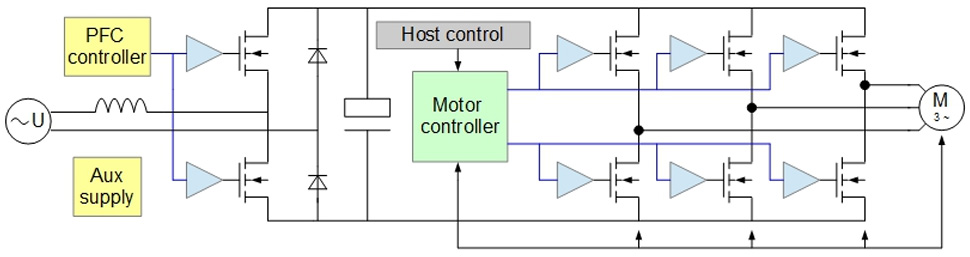

These higher efficiency, higher performance motors require more sophisticated electronics for operation. Pulse-width modulation (PWM) techniques for variable-speed drives (VSD) or variablefrequency drives (VFD) create a pulsed, three-phase voltage for the motor from the rectified AC mains. This leads to enhanced performance, where speed and torque can be controlled, and has a positive impact on the mechanical design of the system. Active power-factor correction (PFC) is implemented on the high-voltage grid side, improving grid stability, which is becoming a more stringent regulation set by governments (e.g. industry standard IEC61000).

Figure 1: A typical variable speed drive consisting of bridge-less ‘totem pole’ PFC, controller and 3-phase inverter stage.

Silicon IGBTs are Slow

For decades, VSDs have used IGBTs as their main power switches. These legacy silicon transistors are robust and cost-effective, but have slow switching speeds and comparatively high losses, leaving room for improvement. For many consumer applications – in particular those expected to operate indoors – switching frequencies above 16kHz are required to reduce audible noise. These higher frequencies are challenging for IGBTs due to their slow reverse recovery characteristics, resulting in high switching losses. Silicon MOSFETs have been used for VSDs as well, but the power density achieved is lower than IGBTs even though switching losses can be lower at full load conditions. MOSFETs can also have very poor internal body diode recovery losses that add to total losses. Even specially designed MOSFETs with fast recovery diodes are typically slower and snappier than fast recovery diodes in IGBT products. In light-load operation, MOSFETs do show advantages over IGBTs due to their linear current-voltage relationship.

Benefits of GaN in Motor Drives

The next big step in efficiency, both in the inverter and motor as well as in the overall system can be achieved by using gallium nitride (GaN) in the power stages. GaN-based devices are much closer to the ideal switch, offering significantly lower switching losses, resulting in many different benefits.

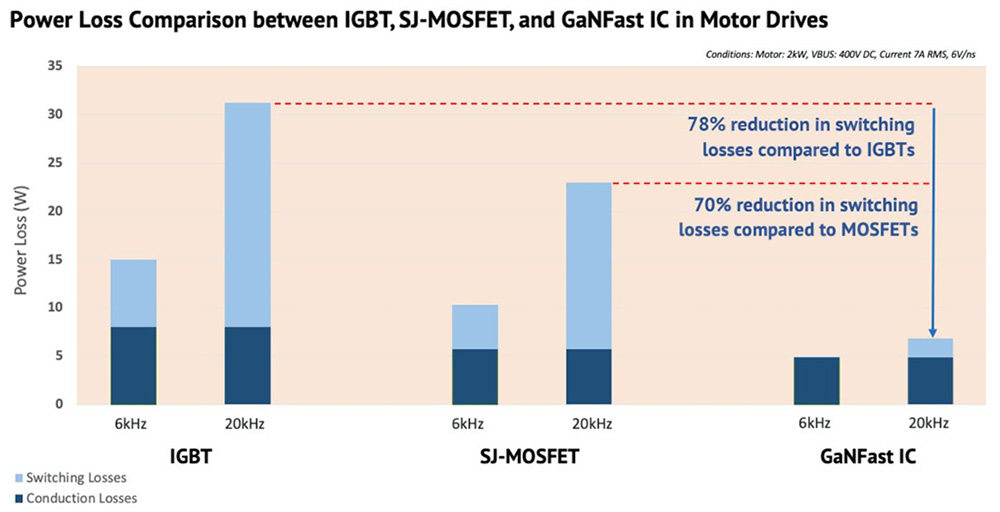

In most cases the efficiency of a VSD is relatively high, typically 95%-97%, which is much higher than the motor or the mechanical process that is being driven. Older motors had 60% efficiency, and the more modern BLDC motors operate at 80% or higher. These higher-efficiency VSD systems offer better electrical efficiency, due to very low switching losses, which results in lower system cost, as the heat sink necessary to remove the heat from the power switches can be significantly reduced, or even removed. In hard-switched half-bridges, which are typical for VSDs, the lower switching losses of GaN ICs, which have zero reverse recovery losses, can be 4x-5x lower than for IGBTs or MOSFETs, reducing total power losses by 50%. In low-power applications, this may even mean the complete removal of the heatsink. With heatsink-grade machined aluminum priced at $6 – $8/kg – and reaching a 13-year high in 2021 – this has a significant cost implication to the system. Additionally, reduced weight leads to lower shipping cost, further reducing total cost of ownership (TCO).

Figure 2: Navitas GaNFast ICs exhibit lower losses across all switching frequencies, but significantly as switching frequency increases (Source: Navitas Semiconductor calculations)

Navitas GaNFast™ ICs integrate driver with enhancement mode FETs, where two-dimensional electron gas density (2DEG) creates electron mobility. With no active PN junctions, no inherent body diode exists leading to no reverse recovery charge in the device. This significantly reduces switching losses and provides smoother voltage waveforms during switching events, with minimal ringing, resulting in increased performance and system reliability and lower system cost.

With no QRR, GaNFast ICs become ideal for hard-switching designs such as half-bridge topologies, where the lowest switching losses occur during high- and low-side switching transitions. The deadtime necessary between the two switches can be shortened dramatically, from around 2,000 ns down to 50ns. For motor drive applications, this leads to a significant reduction in torque ripple and audible noise, improving the lifetime of the system [7].

Autonomous, Reliable Power: GaNFast with GaNSense

To solve that problem, GaNFast power ICs integrate GaN power (FET) and GaN drive plus control and protection in a single SMT package. The result is reliable, easy-to-use, high-speed, highperformance ‘digital-in, power-out’ building blocks. Since qualification in early 2018, GaNFast ICs have become the industry-leading solution for fast and ultra-fast mobile chargers, employed by customers including Samsung, Dell, Lenovo and LG. As of March 2022, over 40,000,000 units had been shipped with zero reported GaN-related field failures.

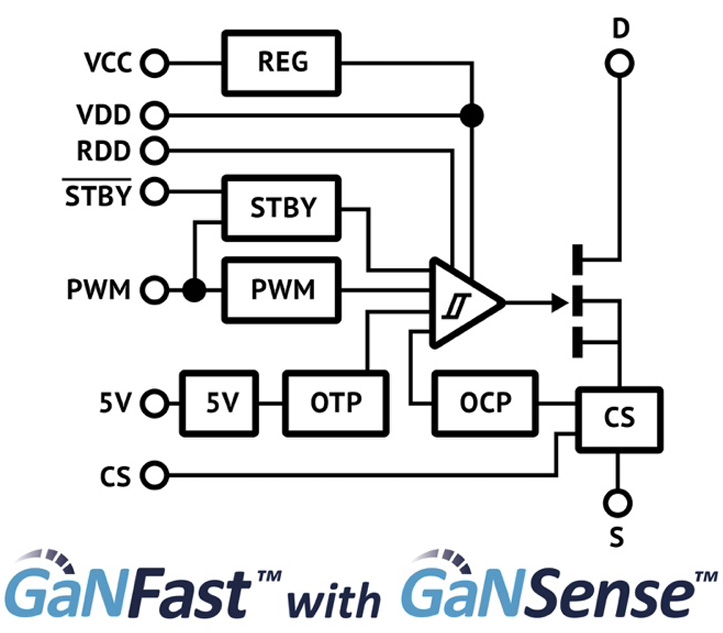

Figure 3: Simplified block diagram of the fully integrated GaNFast with GaNSense ICs from Navitas incorporates control, drive, sensing and protection features [8,9]

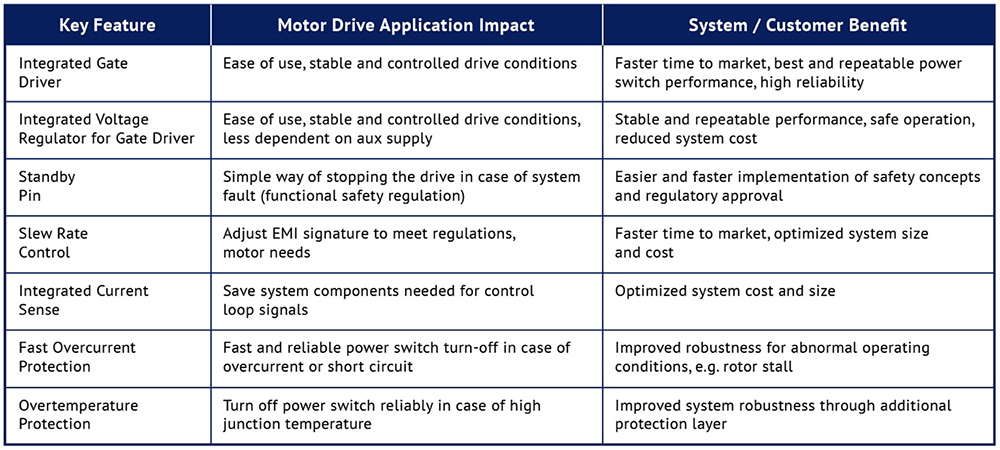

The result is optimized and repeatable inverter performance, enabling excellent reliability – the power switch can be controlled with a simple digital signal, removing lots of external components, improving size and component count even beyond silicon solutions [8]. This is good news for compact motor drives, where the size of the VSD can now get so small it can easily fit in with the motor housing.

In 2021, new GaNFast power ICs with GaNSense™ technology introduced system sensing functions, such as over-temperature and over-current detection, and the autonomous ability to self-protect. Compared to discrete silicon or discrete GaN approaches, GaNSense technology can ‘detect and protect’ in only 30 ns – 6x faster than silicon or GaN discretes – improving system-level reliability.

Lossless current sensing enables removal of large and expensive shunt resistors, further reducing system size and cost while maintaining fast overcurrent protection for system robustness. This is important in industrial motor drives for factory automation and helps designers to implement functional safety concepts in their products [9].

An over-temperature protection circuit enables temperature measurement of the power switch in the package, whereas a temperature sensor on the heatsink has much lower precision. This is important for many industrial and consumer motor drive applications, where the cooling system may be adjusted with liquid flow rate or a cooling fan. The built-in over-temperature protection circuit will turn off the GaN IC in case of too high a temperature, protecting the system [8].

Table 1: GaNSense key features provide significant benefits in performance, efficiency, and reliability for motor drive applications

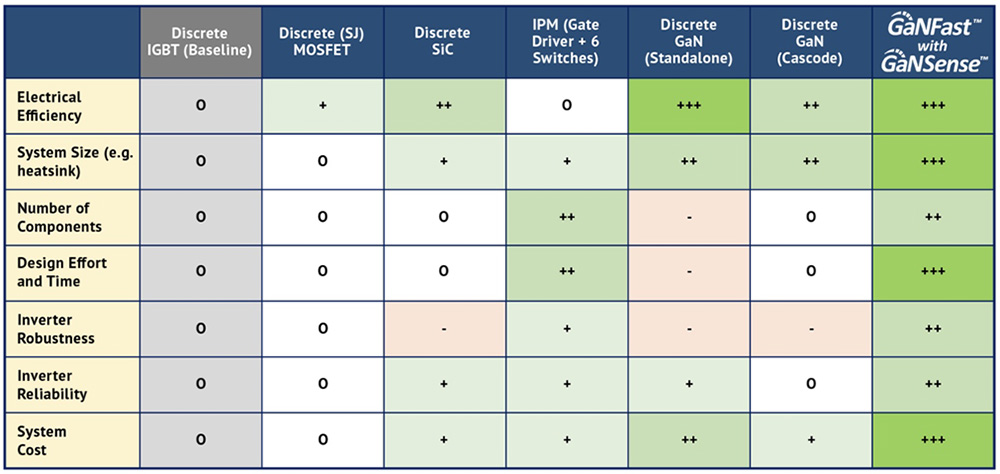

Motor inverters have been implemented in many different ways, predominantly using IGBTs for their low cost and current handling capability. Table 2 compares the approaches available nowadays (discrete IGBT = baseline):

IPMs, or “Intelligent power modules”, combine a gate driver with the six power switches in one package, saving system size and component count, while reducing the design effort.

Silicon MOSFETs, in particular superjunction MOSFETs, have seen increased use in motor drives, improving the light load efficiency. Even better efficiency across the full load range can be obtained with SiC MOSFETs, at the expense of reduced short circuit withstand time.

Discrete GaN FETs help to reduce power dissipation even more, but complex gate drive circuitry needs to be implemented by the designer. GaN cascode components can offer standard gate drive, though at the expense of higher power losses and cost.

GaNFast ICs with GaNSense enable the inherent efficiency of GaN FETs without having to deal with a complex gate-drive circuitry. The loss-less current sensing eliminates shunt resistors and improves efficiency, space, and cost, whilst the integrated protection circuits enabling robust inverter solutions with little design effort.

Table 2: GaNFast ICs with GaNSense integrates gate drive complexity, autonomous protection, with loss-less current sensing, providing compact, easy to design, robust systems

Summary: Integration Drives Performance

Not every motor drive is the same and the trends in consumer and industrial applications are focused on increased energy efficiency, performance, system cost, and total cost of ownership, and reduced size and weight. This represents a formidable challenge to design teams around the world, with pressure to reduce design times and time-to-market, whilst improving end customer experience. GaNFast ICs with GaNSense offer a fully integrated solution of power, driver, protection and sensing features that enable next generation motor drive systems to take advantage of GaN FET performance and advanced sensing techniques, with the peace of mind of providing the requisite robustness and protection.

References

1) ec.europa.eu, “Electric motors and variable speed drives”

2) Overview on EU regulations, e.g. https://www.coolproducts.eu/product/washingmachines/

3) IEC standard 60034 (Industrial motor efficiency classes)

4) Regulation on electric motors and variable speed drives (EU) 2019/1781

5) Smart Water Magazine on smart solutions from Grundfos, 2019, https://smartwatermagazine.com/news/grundfos/grundfoss-smart-water-solution-deployed-over7000-villas-across-uae

6) LG (South Korea), “6 Motion direct drive”, https://www.lg.com/uk/washing-machines/lg-aidd

7) US patent 8390241 “Motor drive based on III Nitride devices”

8) Navitas Semiconductor, “GaNFast™ Power IC Solutions for EV, Solar & Industrial,” Bodo’s Wide Bandgap Event, Dec 2021

9) Navitas Semiconductor, “GaNFast™ Architecture, Performance in High-Power Systems,” Bodo’s Wide Bandgap Event, Dec 2021

10) Navitas Semiconductor, Application Note AN-015, Dec 2021

11) IEC standard 60730 (Functional safety in Consumer applications), 68100 (Functional safety in Industrial installations)