EVs for Energy Efficiency and Energy Independence

Driving you home, and driving your home!

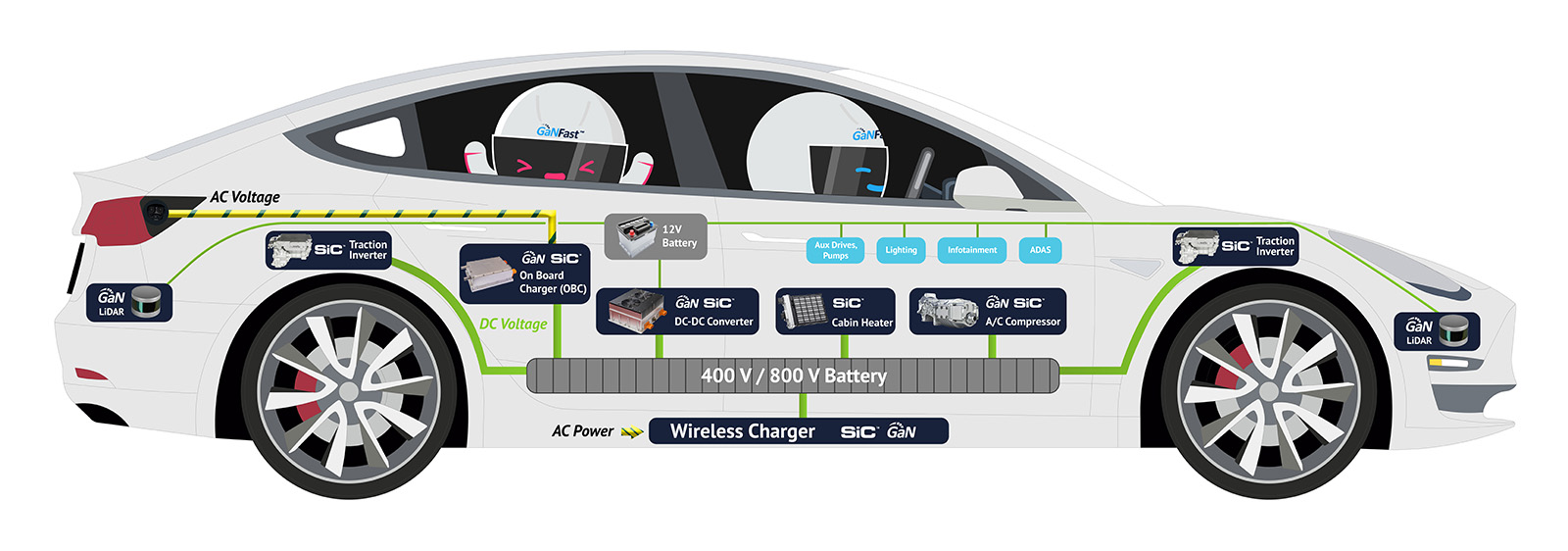

Next-gen GaN and SiC are critical and complementary technologies for EV applications. As the only ‘pure-play’ next-generation power semiconductor company, Navitas can help to accelerate worldwide adoption of EVs by 2 years vs. legacy silicon chips, in a market estimated at over $12B/year by 2030, with:

-

- Up to 3x faster charging

- Up to 70% energy savings

- Longer range

- Lighter weight

- Faster acceleration

- Lower cost

- Safer operation

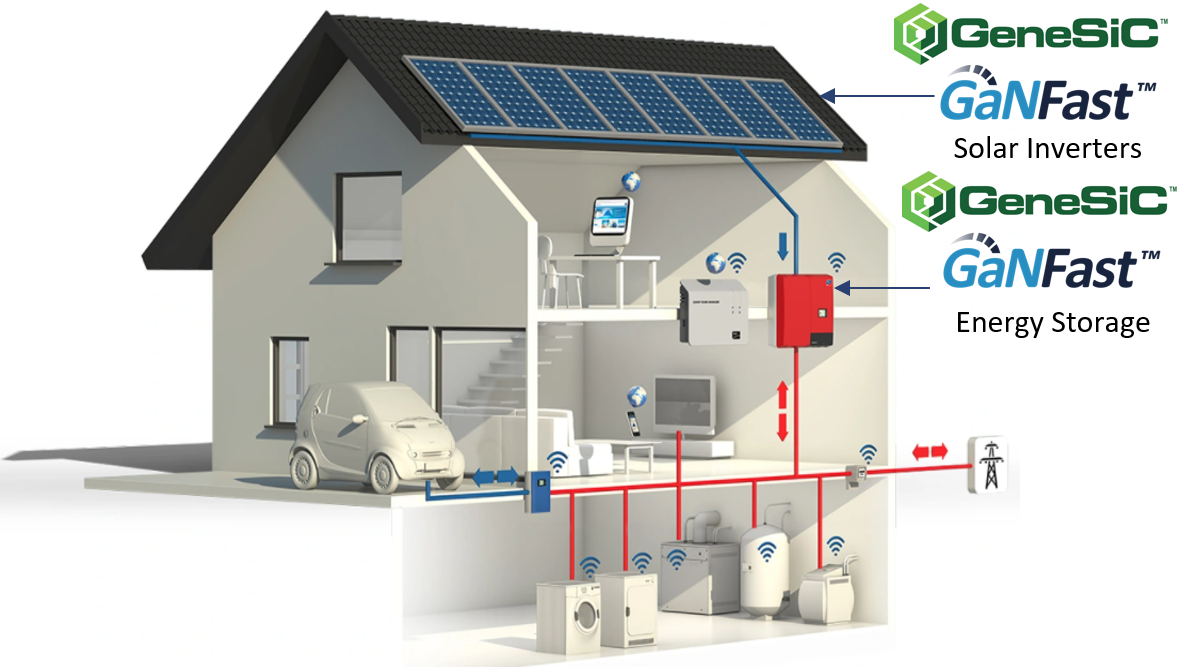

EVs can also act as supplementary energy back-up for your home to balance energy supply (from mains AC, solar, generators) and demand (Wi-Fi, heating, cooling, cooking), and be a critical part of an energy-independent micro-grid in the event of a mains AC failure. This is known as “V2x” (vehicle to anything) charging, and can be:

-

- V2V – one VE charges another

- V2G – power returns to the AC grid, and

- V2H – your EV powers your home

Roadside Charger

Roadside charging has evolved quickly, from Level 1 ‘trickle-charge’ (0.8-1.3 kW/hr, 110 V AC), to Level 2 (3.3-19.2 kW/hr, 240 V AC) and now ‘DC fast charging’ (up to 350 kW/hr, up to 800 V DC), known as ‘Level 3’, which for the new Genesis GV70 SUV, enables 10-80% charging in 18 minutes!

New architectures have increased the working bus voltage from 1,000 to 1,500V to increase power density, simplify designs, improve efficiency, reliability and system cost. A 1,500V bus requires up to 3,300V SiC device capability, to cover all main and auxiliary power applications – and GeneSiC is the leader in high-voltage SiC. An example roadside charger customer, with a 350 kW design, has over 50% share in the US high-speed charger market, and aggregated SiC shipments of 1,000,000-pieces are expected by the end of Q2 2023.

On-Board Charger (OBC)

The OBC takes in AC power and converts to a high-voltage (400 V or 800 V) DC power for the EV’s on-board battery. 650 / 700 V-rated GaNFast power ICs are optimized for high-speed switching and connection to both the AC line, and 400 V batteries. With superior high-voltage capability, 1,200 V GeneSiC MOSFETs and diodes connect efficiently and reliably to 800 V battery systems.

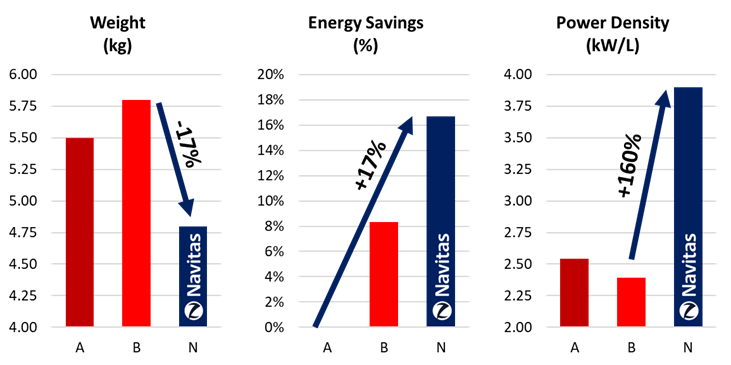

Passenger car OBCs range from 6.6 to 22 kW, and due to higher switching speeds, and higher efficiency, GaN/SiC OBCs can be up to 3x smaller – or provide 3x more power for 3x faster charging – than legacy silicon systems.

A key development in EV OBCs is ‘bi-directionality’ – which means that the car is no longer simply an energy use, or load, but can be an energy source as in “V2x” mentioned earlier.

Bi-directional OBCs are already available in the Nissan Leaf, Ford F-150 Lightning, Hyundai Ioniq 5, Kia EV6 and the Mitsubishi Outlander PHEV.

Click here for more information about Navitas’ bi-directional OBC platform designs.

DC-DC Converter

While high-power functions – like the main traction drive – are connected directly to the high-voltage (400 V / 800 V) battery stack, many applications like navigation systems, Lidar, seat motors, windshield wipers, etc. are low voltage, usually 12 V.

DC-DC converters step down the voltage and provide safety isolation, using a combination of GaN and SiC devices at high speed with up to 20% energy savings, up to 3x smaller, up to 20% lighter, plus the reduced cost of passive components.

For 400 V systems, click here to learn more about 650 / 700 V GaNFast power ICs, and for 800 V systems, click here to learn more about 1,200 V and 1,700 V GeneSiC MOSFETs and diodes.

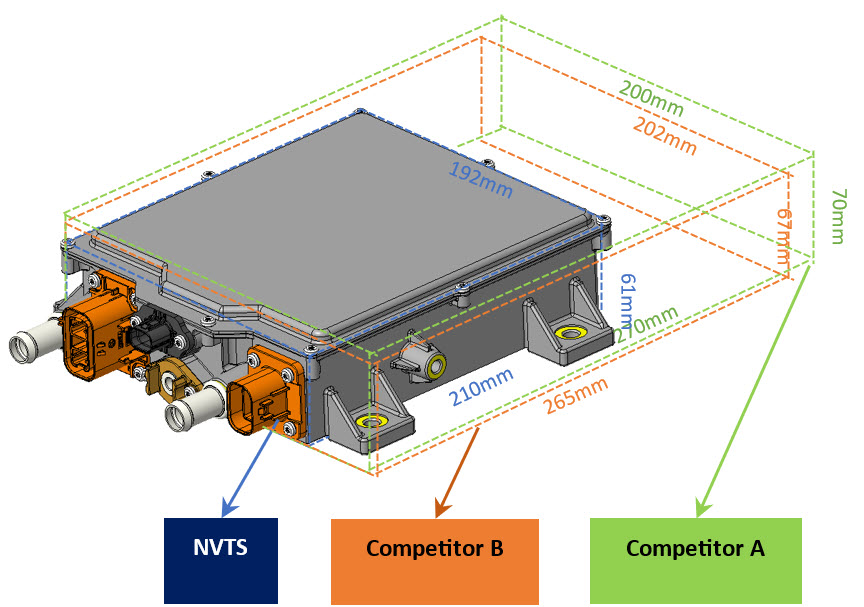

3-in-1 Bi-directional OBC plus DC-DC

EVs can play a vital role in managing variants in power supply and demand, and reduce stress on the grid infrastructure. Acting as an energy reservoir, or energy source for other loads, EVs enable a “V2x” network, where a vehicle may charge a home, a clinic, or another vehicle. GaN and SiC can play a role in advanced, bi-directional topologies like ‘CLLC’ and due to high speed, can shrink and consolidate power converters.

Bi-di 6.6 kW OBC

Interleaved CCM T-P

Bi-di CLLC

AC Voltage:

DC Voltage:

Power:

Efficiency :

100 kHz

450~900 kHz

90 ~ 265 VAC up to 32 A

250~500 V, 280~460 V

6.6 kW charging

6.0 kVA discharging

>95.0% @ full load

>96.2% charging mod

3.0 kW DC-DC

Hard-switch DC-DC:

Output:

65 kHz

9~16V

Size:

Cooling:

Others:

210 x 192 x 61 mm <2.5 L

-40~65°C liquid cooled

IP 67, CAN interface

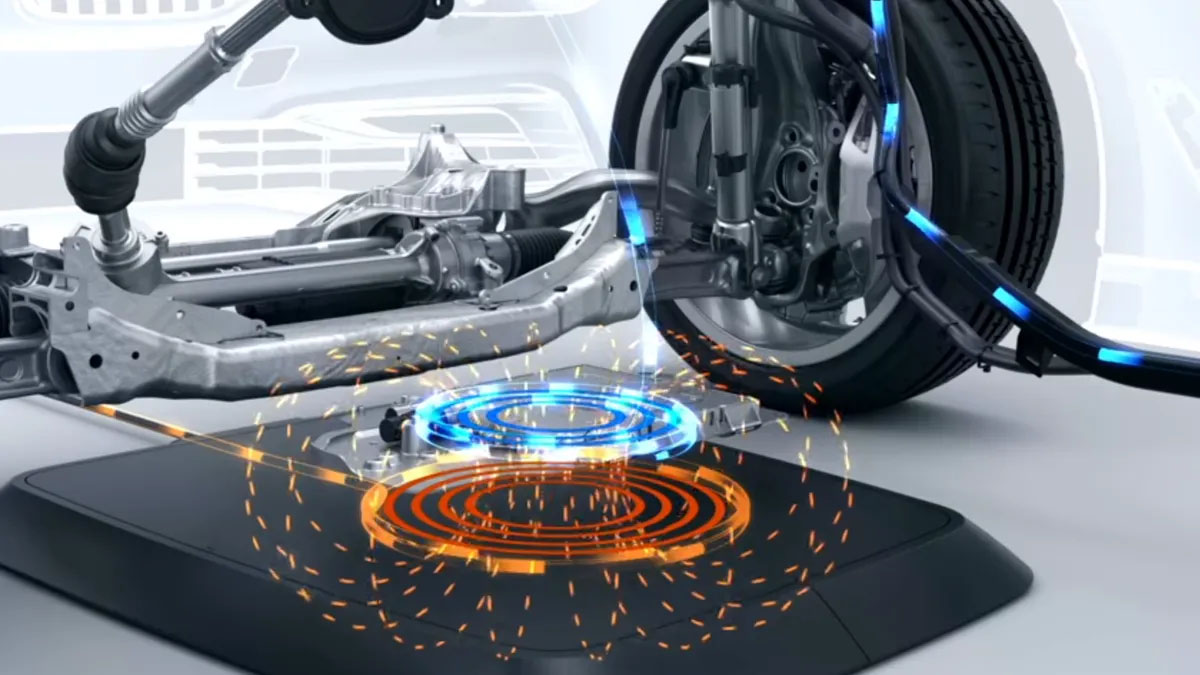

Wireless Charger

In many EV applications, an optimized ‘contact-less’ power connection is required. For example, in commuter routes where a bus can be charged from beneath in the dwell time at a bus stop, while passengers enter and exit, when taxi drivers are waiting for a fare, or where AI warehouse robots can be charged at a remote location without a human to connect and disconnect charging cables.

In the ‘light duty’ EV market, an industry standard – SAE J2954 – was ratified in 2018, and updated recently in October 2022 to define power ranges (3.3 – 11 kW) and frequency (81.39 – 90 kHz) to allow interoperability.

Both GaN and SiC have higher-speed performance (lower capacitance) than legacy silicon chips, so operate more efficiently with cooler, longer-lifetime operation.

Source: BMW

In consumer applications, cellphones and earbuds can be charged wirelessly using ‘Qi’ (~100 kHz) or AirFuel (6.78 MHz) protocols, at lower powers.

Click here for more information on GaNFast power ICs at 6.78 MHz.

Traction Inverter (Motor Drive)

The traction inverter takes power from the battery and uses it to turn the main motor(s) in the EV, usually in a 3-phase bridge architecture. High-efficiency, high-speed, high-reliability GeneSiC MOSFETs are optimized for these high-voltage, high-current conditions.

Running at high frequency shrinks the drive stage by 3x, with lower weight and system cost, with estimated performance of over 99% peak efficiency, and up to 10% longer range.

Click here for more information on GeneSiC MOSFETs and diodes, ranging from 650 V to 6.5 kV.

Air-Conditioner (AC) Compressor

Air-conditioners cool the EV’s passenger compartment using the classic refrigeration technique of increasing the pressure of a liquid, which then cools as it expands. In an EV, the compressor is typically a 3-phase motor drive, with GaN or SiC MOSFETs chose per the battery voltage.

Compared to legacy silicon IGBTs, GaN or SiC compressor drive stages can be up to 3x smaller, with over 98% efficiency.

For 400 V systems, click here to learn more about 650 / 700 V GaNFast power ICs, and for 800 V systems, click here to learn more about 1,200 V and 1,700 V GeneSiC MOSFETs and diodes.

Cabin Heater (PTC)

GeneSiC SiC MOSFETs have the industry’s smallest increase in resistance over temperature – which in the vast majority of applications is a critical advantage in efficiency and reliability. In a cabin heater, this small increase in resistance is used in a self-regulating, safe, efficient way to provide heat to the EV’s passenger compartment. ‘PTC’ stands for ‘positive temperature coefficient’ and as the temperature increases, the resistance of the SiC MOSFET increases, and current is reduced or stopped automatically.

Compared to silicon IGBTs, SiC systems have higher efficiency (>95%), are smaller and lighter.

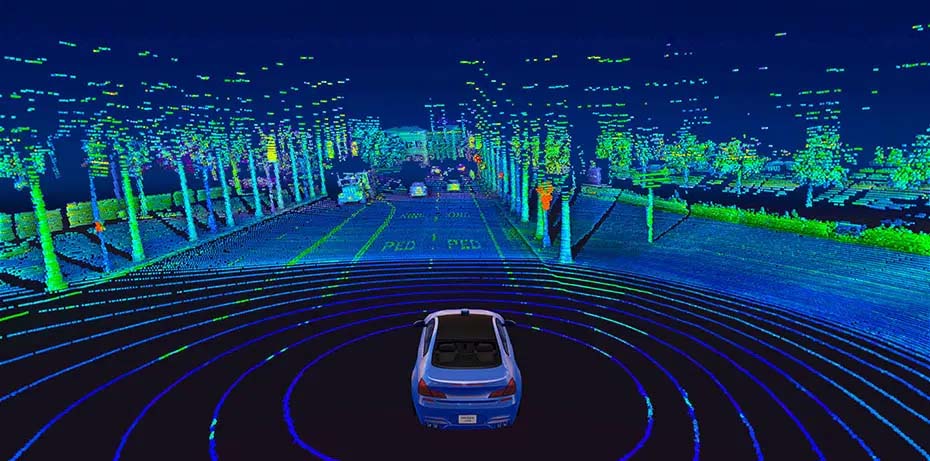

Lidar

Image: Velodyne

Lidar, or “Light Detection And Ranging” is sometimes called “laser scanning” or “3D scanning” to create a 3D representation of the landscape, using millions of laser pulses per second which are reflected back and monitored.

With less than 2 ns pulse-width, enabled by GaN’s 10x higher-speed switching performance vs. silicon, delivers higher-resolution, more accurate results regardless of weather, with lower power consumption. Higher pulse current (>100 A) delivers longer range, and a more responsive, safer result.

As with power conversion applications, LiDAR systems with GaN are smaller, lighter and with lower system cost.