Electrify Our World™ – The Next-Gen Transition in Your Kitchen

Let’s see what’s cooking…

Today, 80% of energy uses are fossil fuel based. Cars are the obvious example, but we also need to discover how natural gas cooking, heating/cooling and other uses can be electrified, and how next-gen GaN and SiC can accelerate the transition to zero CO2 at point-of-use, and upgrade old silicon systems to save up to 6 Gtons/yr of CO2.

For more information, watch Weka Media’s interview with Navitas’ Alfred Hesener via the Navitas YouTube channel.

Refrigerator

At the same time, we now have IoT-connected refrigerators, with interactive large-screen displays, ice makers and filtered water.

GaNFast power ICs convert AC power to 400 V DC for the compressor, and step down to 12 or 24 V for screen, fans, ice maker, etc. GeneSiC MOSFETs (650 V, 750 V) are an ideal solution for the compressor’s low-noise BLDC, with the industry’s best high-speed, high-temperature operation.

Washer / Dryer

Today’s combination washer / dryer is optimized for small size, low water use, low electricity use, shorter cycles, faster spin and ventless drying… with WiFi connectivity!

The high-power ‘direct drive’ motor is powered by a 3-phase array of SiC MOSFETs.

An auxiliary power supply is required to power the display, light, and small pumps.

Dishwasher

Today’s dishwashers have many sensors, pumps, heaters, and intelligence built in to provide the most cleanest and flexible wash cycles, while monitoring and communicating remotely.

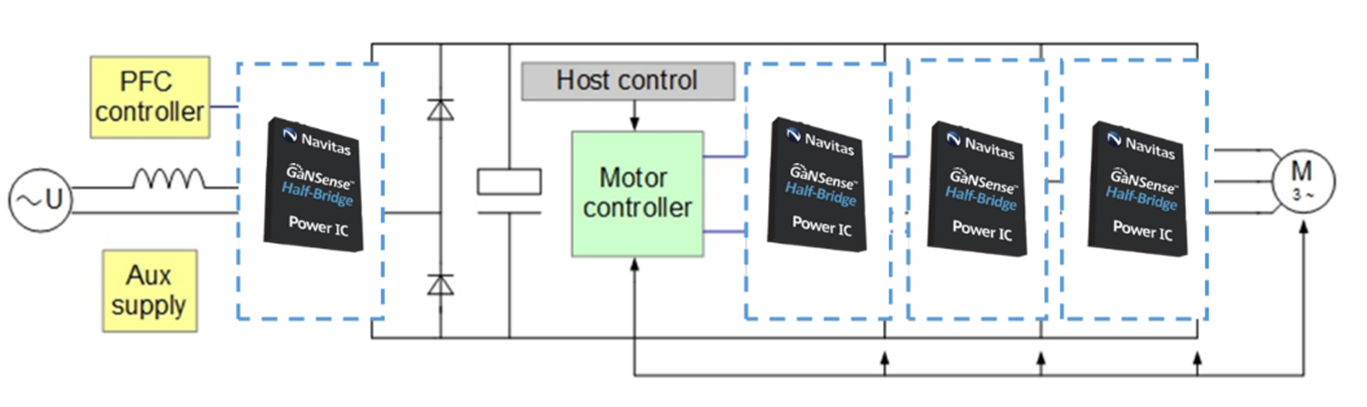

Variable speed pumps are used for circulating and draining. 3-Phase topologies requiring 6 GaN power ICs are used to offer the highest efficiency, reduced EMI, and low acoustic noise.

An auxiliary power supply allows the control panel to operate and communicate, while also supplying power to the sensors, fans, and displays.

Air-conditioner / Heat Pump

Most HVAC systems only run at one speed. New variable-speed drive (VSD) systems have multiple settings, letting it match your heating and cooling needs precisely.

A variable-speed air conditioning system will provide additional energy savings, improved comfort, and better indoor air quality.

As they do not run only at full-speed, less electricity is consumed which results in lower electricity bills. Additionally, variable speed reduces wear and tear, therefore increases lifetime and reliablity.

An air-conditioning system and heat pump system consist of a high-power compressor and lower power fan. Each require 6 GaN power ICs or SiC MOSFETs in a 3-Phase configuration to implement the pulse width modulation (PWM) for variable speed driving.

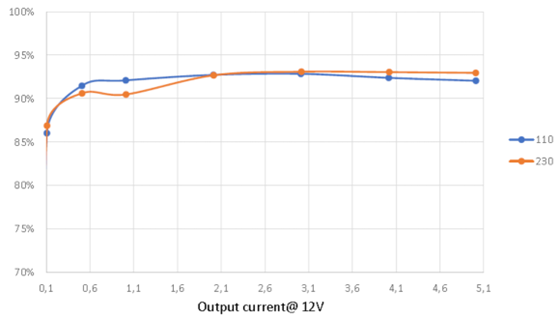

60 W Auxiliary Power Supply for Home Appliance

GaN power ICs provide higher energy savings, lower system cost and smaller size. The highly-compact, integrated design has a wide input range and no heatsink is needed. The design achieves >93% efficiency (at 50% load), much higher than comparable silicon designs which reach only 85%/ The high switching frequency up to 300 kHz enables the smallest size transformer.

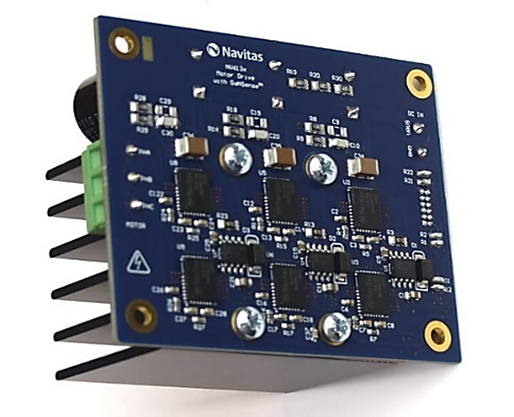

400 W Home Appliance Motor Drive

Motor Drives are used in many home appliances. From hair dryers to air conditioning systems, dishwashers to refrigeration. Anything that turns, needs a motor.

Variable Speed Drives (VSDs) create a pulsed, three-phase voltage for the motor from the rectified AC mains. This leads to enhanced, performance, where speed and torque can be controlled more efficiently.

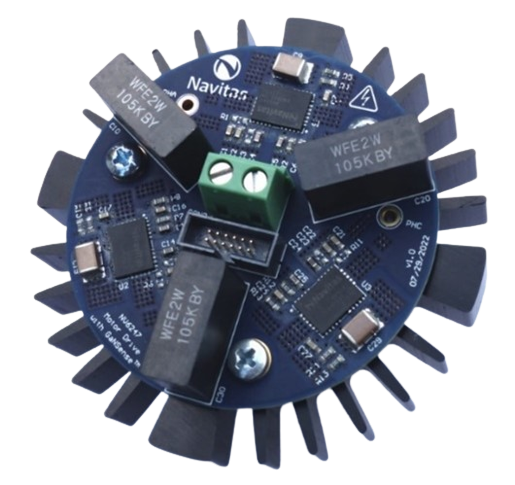

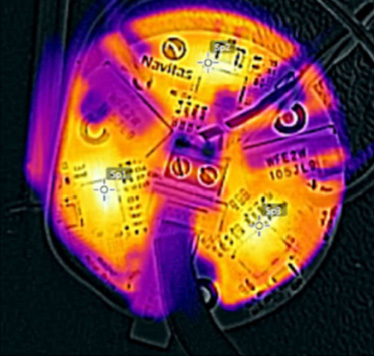

3x NV6245 / 6247

Operation at 300W, 20kHz, 25°C,

NV6247: Peak temp. 52°C without heatsink

GaN power ICs provide superior performance resulting in energy savings and lower system cost.

Up to 70% smaller and 60% fewer components are used compared to traditional silicon solutions

GaN power Ics are capable of very high switching frequencies (>100 kHz) to reduce EMI, acoustic noise and reduce passive components

GaNFast power ICs with GaNSense technology integrated loss-less current sensing and integrated protection (OCP / OTP), to provide highest reliability, lower compoenent count, and ease of desgn for faster time to market.

The 400W (without heatsink)Evaluation Board offers a highly compact design with high integration and protections.

| Part # | Type | VDS(CONT) (V) | RDS(ON) (mΩ,typ) | Package | Status | Motor power* |

|---|---|---|---|---|---|---|

| NV6247 | Half-Bridge | 650 | 160/160 | PQFN 6x8 | Production | 300 |

| NV6245C | Half-Bridge | 650 | 275/275 | PQFN 6x8 | Production | 200 |

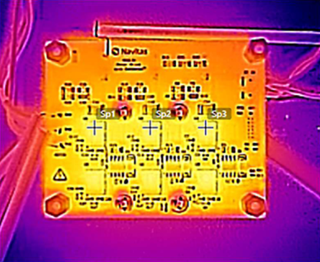

1 kW Washing Machine Motor Drive

NV6138

Operation at 500 W, 20 KHz, 25°C. Peak temperature 51°C

Washing machine moved to variable speed drive motor drives several years ago to improve efficiency, performance, and reliability.

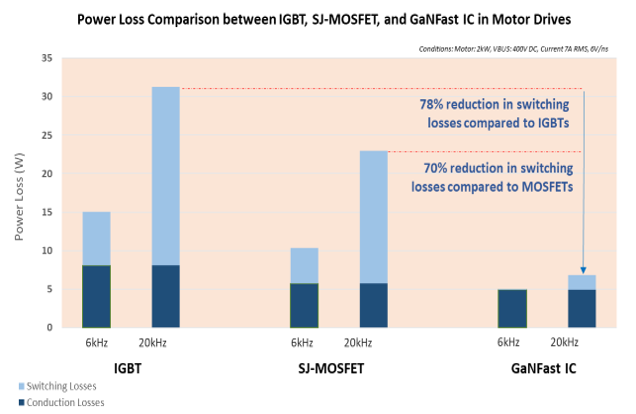

Typically, legacy silicon IGBTs are used as the main power switches. However they have slow switching speeds and comparatively high losses, leaving room for improvement.

For many consumer applications – in particular those expected to operate indoors – switching frequencies above 16kHz are required to reduce audible noise. These higher frequencies are challenging for IGBTs due to their slow reverse recovery characteristics, resulting in high switching losses.

Next generation motor drives use GaN-based devices which are much closer to the ideal switch, offering significantly lower switching losses, resulting in many different benefits:

-

- 70% smaller and 70% reduced power losses than traditional silicon solutions

- Capable of very high switching frequencies (>100 kHz)

- Eliminates shunt resistors with integrated loss-less current sensing

- On-chip OCP / OTP, for precise thermal design

- Easy to use / Fast time to market