Gallium Nitride: Catalyst for the Next Generation of Power

![27_Pdf_File_Type_Adobe_logo_logos-512[1]](https://navitassemi.com/wp-content/uploads/2020/12/27_Pdf_File_Type_Adobe_logo_logos-5121.png)

Gallium Nitride: Catalyst for the Next Generation of Power

Gallium Nitride (GaN) comes-of-age to meet 5G needs, enable new topologies and revolutionize fast charging.

by Stephen Oliver

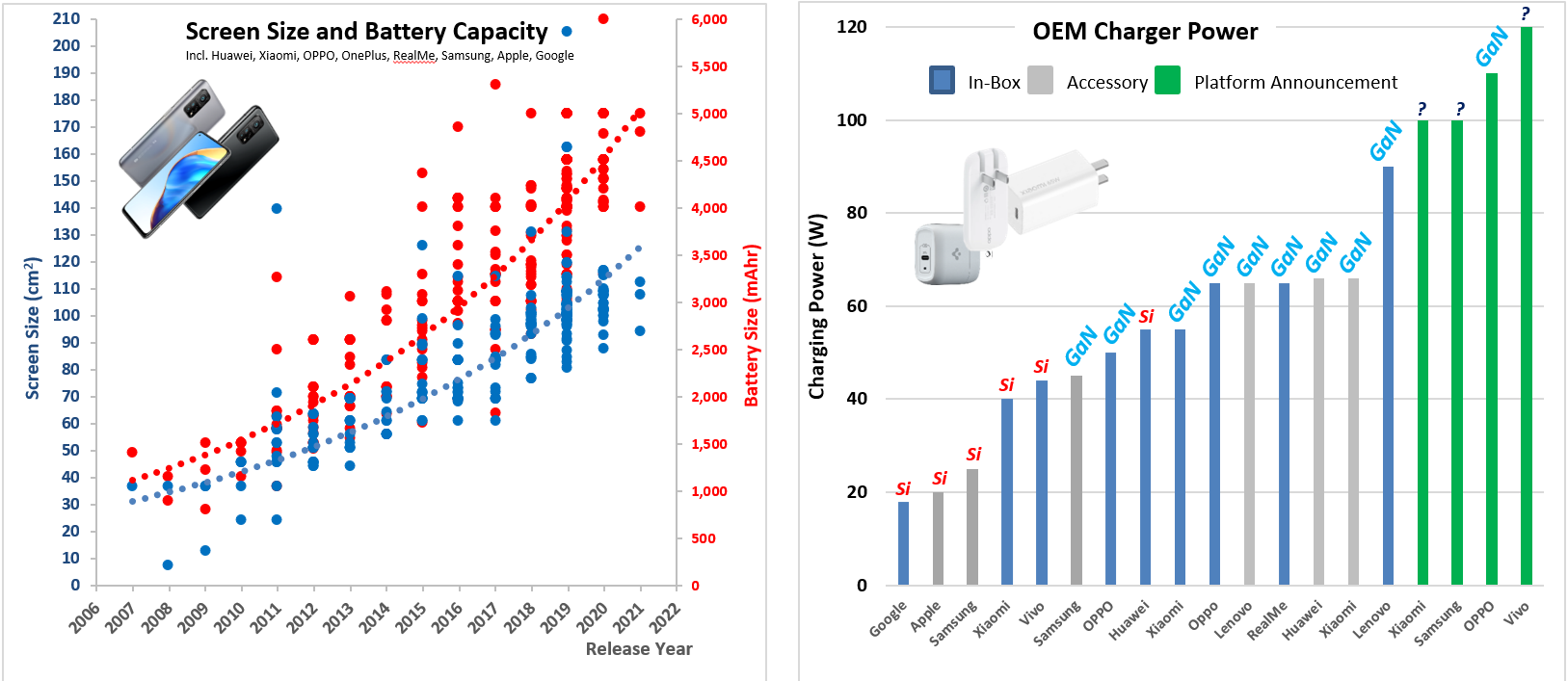

Since 2010, the average screen size (cm2) and battery capacity (mAhrs) for new phone platforms like the Apple iPhone 12, Xiaomi Mi11 and Samsung S21 have increased over 3x, as shown in figure 1 (compiled from data published by GSMArena). Using slow, silicon- based 5W or 20W commodity ‘in-box’ chargers leads to unacceptable, extended charging times, so more power is required. To get more power from a silicon charger means more size, more weight and more cost – as traditional, low-frequency topologies dictate that designs are power-density and heat-density limited.

Figure 1: Smartphone screen-size and battery capacity has increased over 3x in 10 years. As new platforms have been released with faster charging rates, OEMs have

moved to adopt gallium nitride (GaN) chargers for both accessory and ‘in -box’ options. Source: GSMArena, Navitas as of January 2021.

The key to improved power density is increased switching frequency to minimize passive components such as transformers, EMI filters, bulk and output capacitors, etc. High-speed topologies such as the active-clamp flyback (ACF) have been proposed by academics since 1996i but were frustrated by silicon’s poor on-state (RDS(ON)) and switching (QGD, Trr, COSS) performance plus complexity and lack of optimized control ICs. In early 2018, the introduction of the GaN power IC ended that frustration and enabled commercial viability of not only the ACF but also high-frequency quasi-resonant flyback for smartphone chargers, plus topologies such as CrCM boost PFC, high-speed LLC and advanced CrCM totem-pole PFC for higher-power systems such as gaming laptops, all-in-one PCs, TVs and 5G transmitter cell power.

A gallium nitride power IC monolithically-integrates GaN power (FET) and GaN drive plus control and protection in a single SMT package. These “GaNFast™” power ICs become easy-to-use, high-speed, high-performance ‘digital-in, power-out’ building blocks. Integration enables virtually zero loss in turn-off because the gate drive loop has essentially zero impedance. In addition, turn-on performance can be controlled and customized for specific application requirements.

The result is that GaN power ICs enable 3x faster charging in half the size and weight vs. old, slow, silicon-based designs, and have been adopted by tier-1 OEMs such as Dellii, Lenovoiii, and Xiaomiiv for smartphone and laptop fast charging.

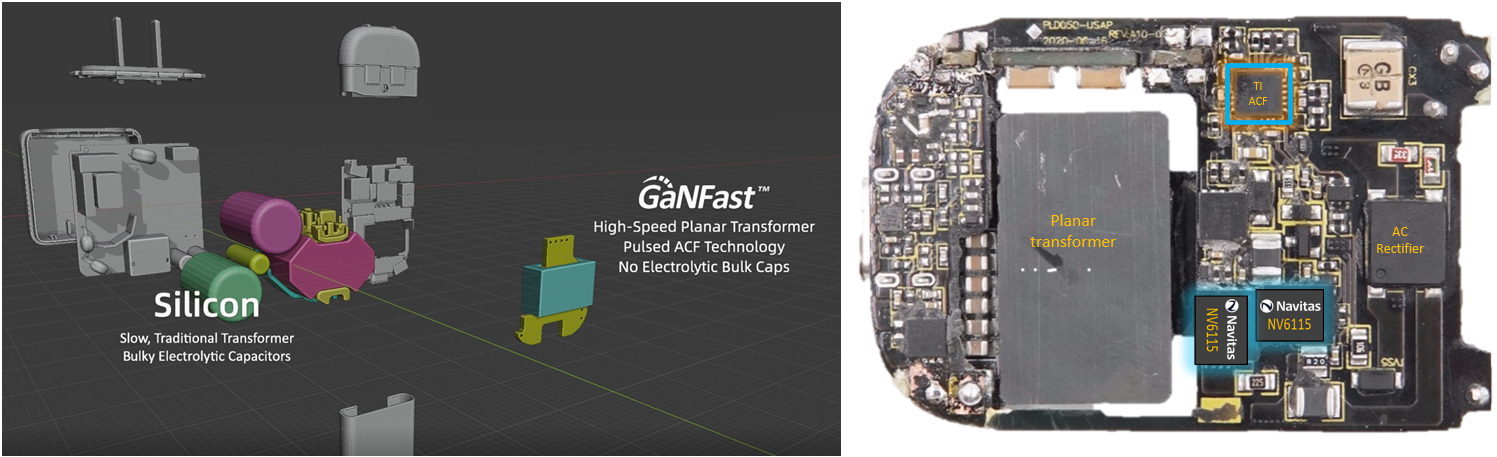

A closer look at the OPPO 50W Mini SuperVOOC “Cookie” fast charger highlights how a high-speed, GaN-enabled topology minimizes or eliminates passive components.

The OPPO 50W Mini uses a 10x higher-speed, high-efficiency ‘active-clamp’ flyback using TI’s UCC28782 controller with a pair of GaNFast power ICs in a half-bridge configuration. High-speed operation (~400 kHz) is possible due to the ‘soft-switching’ topology and the GaNFast power ICs with extremely low resistance (RDS(ON) to minimize ‘on-state’ losses, and minimal output capacitance (COSS) for the best ‘switching’ performance. High-speed now means that the main isolating transformer, EMI filter, output smoothing capacitors, etc. can shrink in size and cost.

Figure 2: OPPO 50W Mini “Cookie” charger, showing high-frequency planar magnetics and elimination of electrolytic bulk capacitor.

In a traditional charger, a large part of the total size is due to the electrolytic ‘bulk capacitor’ used to smooth out ripple from the rectified AC input prior to the down-converting flyback. The ‘bulk cap’ can occupy 40% of the total charger size. In the 50W Mini design, a proprietary innovation creates the world’s first charger using ‘pulsed’ power conversion. This eliminates the electrolytic bulk capacitor, and the rectified 100 Hz pulsating DC feeds directly into the high-frequency ACF circuit which can maintain a smooth output to charge the phone’s battery, even when the input voltage range is wide. This OPPO-proprietary ‘direct- charge’ approach means that during each pulse gap, the polarization effect in the phone battery is eliminated so reducing wear-out mechanisms and extending battery life.

Traditional transformers operate at a few 10’s of kHz and are constructed using toroidal ferrite cores, with separate wire-windings (primary and secondary) to isolate and convert voltage. As operating frequencies increase, a new flat or ‘planar’ transformerv can be created in which the primary and secondary windings are embedded into PCB material – resulting in extremely efficient, high-frequency, low-profile and low-noise (low EMI) systems, while utilizing more automated manufacturing methods for more consistent performance.

Overall, the size difference can be seen comparing a traditional topology with wire-wound transformer (typically over 20 mm) plus large electrolytic bulk capacitor, against the OPPO 50W Mini with new 400 kHz, 8 mm planar transformer and no electrolytic capacitor. The high-speed GaNFast-based Mini is less than half the size of the old, slow, silicon-based version.

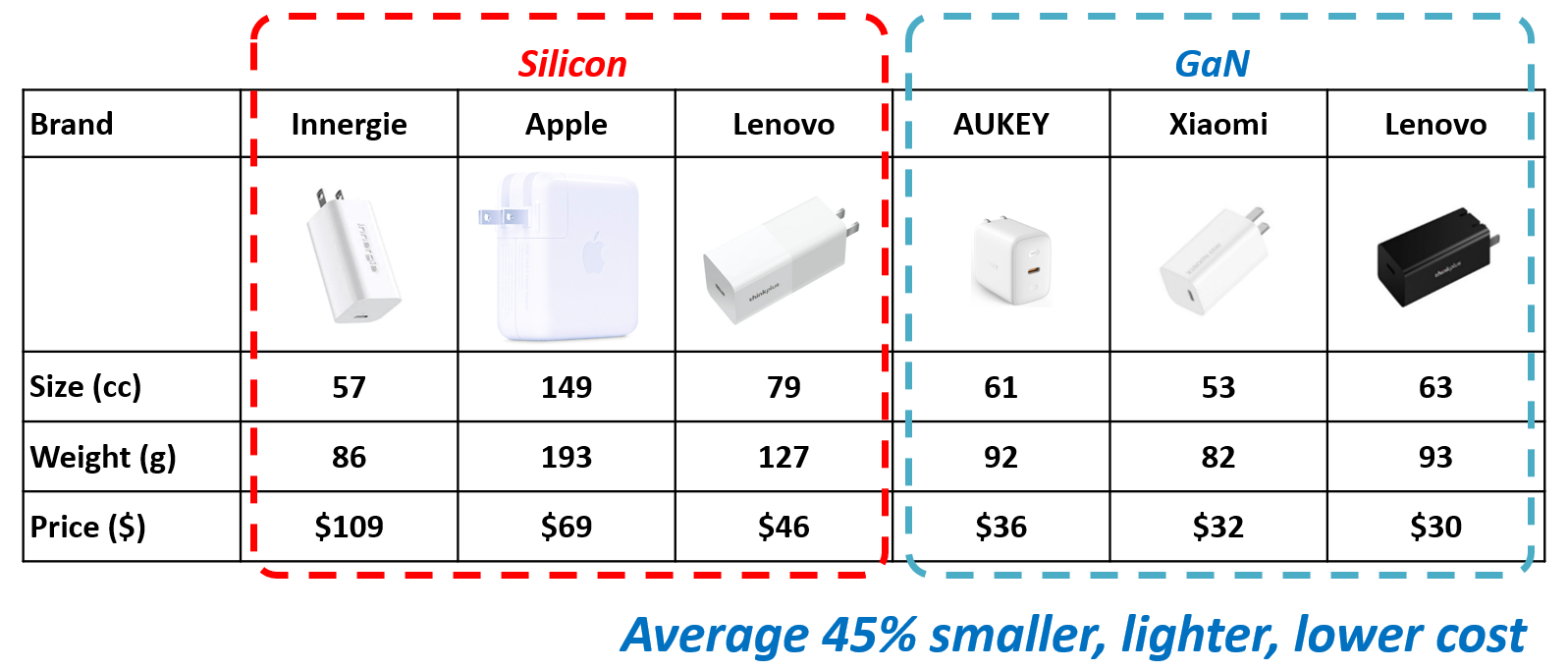

Unlike most new technologies that are burdened with a significant price-tag that limits adoption, the system benefits – and system cost – of GaN-enabled, high-speed chargers mean that retail price is lower than the previous best-in-class silicon designs, as shown in figure 3.

Figure 3: GaN-enabled chargers average half the size, weight and price of previous best-in-class silicon chargers (61W-65W, retail pricing at launch).

To take this one step further, in December 2020, Xiaomi launched the Mi 11vi without a charger in the box, and offered users a simple choice: use an existing charger (and avoid CO2 emissions related to manufacturing and shipping), or receive a GaNFast 65W charger… for free.

As of January 2021, 13M GaNFast power ICs had been shipped with zero failures.vii 40 years after the silicon bipolar junction transistor gave way to the switching silicon MOSFET, we are seeing the ‘second revolution’viii in power electronics, with gallium nitride as the enabling catalyst.

i R. Watson, F. C. Lee and G. C. Hua, “Utilization of an active-clamp circuit to achieve soft switching in flyback converters,” in IEEE Transactions on Power Electronics, vol. 11, no. 1, pp. 162-169, Jan.1996, doi: 10.1109/63.484429.

ii “Dell Adopts Navitas GaNFast Technology for Laptop Fast Charger”, December 2020, https://navitassemi.com/dell-adopts-navitas-ganfast-technology-for-laptop-fast-charger/

iii Lenovo Legion phone launched with 90W GaNFast charger, July 2020 https://navitassemi.com/lenovo-partners-with-navitas-again-to-deliver-the-worlds-first-ganfast- 90w-fast-charger-for-e-sports-mobile-phones/

iv “Navitas‘65W GaNFast charger solution chosen by Xiaomi for Mi 10 Pro”, Navitas, February 2020, https://navitassemi.com/navitas65w-ganfast-charger-solution-chosen-by-xiaomi-for-mi-10-pro/

v Xiucheng Huang, Navitas, “GaN ICs Enabling Next-Gen ACF for Adapter/Charger Application” at APEC 2019, https://navitassemi.com/download/gan-power-ics-enabling-next-gen-acf-for- adapter-charger-applications/?wpdmdl=36529&ind=1561100214576

vi “Xiaomi Mi 11 arrives as the first phone with Snapdragon 888”, GSMArena, December 2020, https://www.gsmarena.com/xiaomi_mi_11_arrives_as_the_first_phone_with_snapdragon_888_brings_1440p_screen-news-46923.php

vii “Navitas Ships 13,000,000 GaNFast Power ICs with World-Class Reliability”, Navitas, January 2021, https://navitassemi.com/navitas-ships-13000000-ganfast-power-ics-with-world-class- reliability/

viii “From Science Fiction to Industry Fact: GaN Power ICs Enable the New Revolution in Power Electronics”, Oliver, Xue & Huang, Bodo’s Power December 2017 https://navitassemi.com/download/from-science-fiction-to-industry-fact-gan-power-ics- enable-the-new-revolution-in-power-electronics/?wpdmdl=37063&ind=1562849999810

GaN, GaNFast and the GaNMan are all copyright Navitas Semiconductor Ltd 2021.

22 Fitzwilliam Square South, Saint Peter’s, Dublin, D02 FH68, Republic of Ireland

www.navitassemi.com

www.ganfast.com

Tel.: ThinkGaNIC +1 (844-654-2642) [email protected]